A Fascinating Glimpse at the Crescent Foods Plant Tour

Growing up in small-town Ohio I had a lot of opportunities to see how things were made, whether they were apples into apple cider at the local orchard, fruits into jam at a small nearby farm or potatoes into potato chips at the area’s largest food factory, it was all part of the things kids did on a field trip or day out with the family. I loved learning at a young age how something went from raw product to an entirely packaged material that people would actually buy in a store- the process fascinated me then and it still fascinates me today.

That’s why I asked if I could go to to the Crescent Foods plant located in oahur backyard here in Chicagoland so I could see how one takes a simple raw product like a whole bird and make it look so clean and beautiful on store shelves- all in a day’s work of this family-run halal poultry business started by Mr. Ahmad Adam and run with help of an incredibly dedicated staff.

They were kind enough to accept my offer. I made my way through downtown Chicago and far into the commercial area of the city where lots of other businesses hold large logistical operations for their companies. Needless to say, it’s a busy area- but how could you miss the fact that Crescent has a presence when their beautifully-photographed trucks are all over the place. Makes you kind of hungry, actually…

I was greeted by the team I’m most familiar with- Joohi Tahir in Marketing, Asma Khan in Operations and of course, Br. Ahmad Adam, the ever-present Founder and CEO as well as his two sons who are a clearly integral part of operating the company so well.

This was clearly a place where serious operations happen. So serious that in order to get into every critical access point of the plant, one has to pass through the state-of-the-art biometric recognition technology (fingerprint recognition)- talk about safeguarding halal right from the start.

As I entered, I got a sense of calm urgency- what I mean is that there wasn’t any sort of frenzy about the place but certainly big things were on everyone’s minds from the woman in HR to the security officer up front watching about 25 cameras (seriously) to the salesman within the offices. I was about to find out all about that.

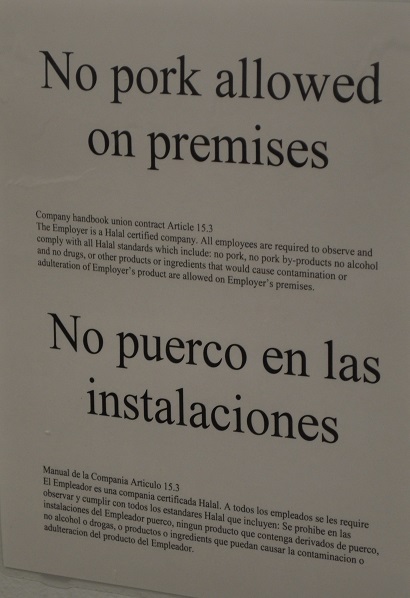

Here was the first sign I saw upon entering:

Don’t mess with the USDA- they can come any time they want, unannounced. That’s their job, and they have an office at the plant to prove it. They check on everything, and if anything at all- big or small- is out of place, the plant can be shut down until things are perfectly back in order.

Keep in mind that no live poultry is at this plant; it’s all raw poultry that’s being processed and packaged.

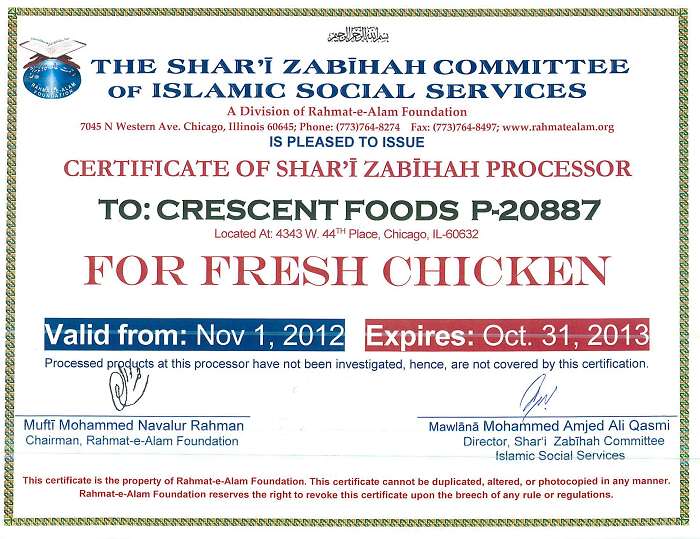

Here was another order of business I saw a little later in the tour, but a paper copy is actually posted at the large garage entrance of the plant where trucks enter the building to load or unload. It’s critical that it be visible to prove authenticity and transparency, which ultimately speaks to the integrity of the business. I was told that the Sharia Board makes unannounced audits to Indiana where the poultry is actually raised and hand-slaughtered.

Also within the over 26,000 SF plant, although inherent or perhaps ‘understood’ in a halal business enterprise, I never expected to actually see a sign that cemented the fact that absolutely no pork would be allowed to enter the premises- it’s also in Spanish, and I saw it in a couple places throughout the plant, particularly where workers gather to eat.

When you visit a food plant, you expect to see machinery, of course. How else would food be shaped, cut, and cranked out so fast, right?

I just didn’t expect to see SO much machinery– and enormous, advanced and well-kept machinery as I did here.

This (below) is the type of stuff that will crank out your kids’ perfectly-formed, perfectly breaded, Halal, antibiotic-free chicken nuggets. I mean, in the thousands…

These machines below were super interesting- we almost need something like this at home, albeit on a smaller scale. They pull the chicken apart as much as possible, separating it so that the remaining parts can be sold to other businesses who use it to make chicken broth or perhaps grind the bones up for pet food, etc. I’m sure there are multiple uses. Just picture the family pet eating halal, too…

If you know anything about Crescent Foods, they sell beautifully-packaged chicken in tray packs and whole fryers in nice and clean bags for easy removal. But, did you know that they also provide their chicken on a wholesale basis to some retailers, too?

And they of course ship their tray packs all across the country, including to many Walmart stores.

As you might realize, it’s not easy to get a product into Walmart. That said, I think I now understand why Crescent products are there. It all makes sense after seeing how wonderfully organized, clean and well-planned out this plant is, of course, but that’s only one element. Not shown here, but they also have an incredibly advanced tracking system to locate every single package that goes out the door and all of their trucks are equipped with GPS systems so that they can be located quickly. It would over-simplify the system if I said it tracked the date/time/lot/destination, as there are so many other variables included that if there’s any issue with any of their products, they’ll know exactly what they need to know to figure out the issue and find a solution- in a nutshell, it’s their recall policy system in place, something they’ve never had to use in eighteen years, alhamdullilah, mashallah.

During the tour, Mr. Adam himself explained to me a lot of technical things that he implemented into the building when he bought it and gutted it completely. It used to be a large warehouse that manufactured elevators- can you imagine what it took to bring it up to an acceptable state for the production of poultry processing? He thought of everything, subhanallah.

If you read my interview with Mr. Adam in the past, you’ll know he is trained as an electrical engineer, so his mind works in ways that can solve problems where others may be confused and overwhelmed by them.

Even the direction in which these tray packs are handled and stored was thought out by Mr. Adam. May seem like something minor, but it matters a lot when you’re dealing with space and efficiency for maximum productivity.

Just my own after-thought, but I wonder if he was implementing tools from Lean Six Sigma when he designed this plant? I should have asked that question..I’m actually taking cues from this- it’s very helpful when designing a kitchen and a home, too- maximum efficiency for productivity is useful anywhere.

Now here’s something I recognize well- tray packs-so that’s how they look before anything is added to them?

This area of the plant is where the tray packs are filled- notice how much protective wear everyone has on- this was very closely monitored by one woman outside of these doors whose job function surrounded making sure anyone who stepped into the factory floor area was covered up properly in order to not contaminate the poultry.

Serious coverage.

And clean, beautiful poultry without any smell. The entire plant didn’t have a smell.

And that’s way it’s supposed to be. Unless things are being actually cooked, food plants shouldn’t have the smell of raw product or rotting foods, obviously. If it did, you would notice.

I couldn’t get over how meticulous the process was and how calm the atmosphere appeared, too. This was probably the loudest area of the plant, but it wasn’t as though you couldn’t hear yourself talking; it was just the machinery that made the obvious and necessary sounds.

And then comes what we, the consumers, recognize the most: labeling.

That’s how it’s done.

I love taking the mystery out of things. Especially meat.

…and how in the world they every get all that plastic around so many large boxes…

…and how it’s all stored, when necessary, in the freezer like it is below (not all Crescent poultry is frozen- actually most of it is sold fresh, but there are some instances in which it is kept colder in order to fulfill a certain shipment. In fact, temperature control is serious business at this plant. I was told specifically, “the production rooms where chicken is handled is maintained at 40 degrees or less to ensure that poultry never reaches any dangerous temperatures. The refrigerated trucks also transport products at this controlled temperature. If the temperature of the coolers or freezer should fall, sensors go off and the security company calls us to tell us exactly at which point and at what temperature it happened. There is 24 hour surveillance.”

And by the way, Mr. Adam even thought about all the venting and cooling systems throughout the plant and installed the very best and most advanced possible in order to prevent any type of cross contamination that might be circulating in the air to contaminate the chicken. Of course those are my words to sum it up. He explained it a whole lot more eloquently and technically than I ever could, but the point is that the lengths that were sought after to ensure the quality and integrity of the product is astounding.

A gutted warehouse not-so-fit-for-a-poultry-processing-plant that has been turned into a state of the art facility where dhabiha halal chicken is centrally located to be shipped to a store near you…it’s truly a feat of humanity, and perhaps you have to have been there to grasp that fact, but I hope some of the photos illustrate the magnitude of importance of this. In a day and age when there is so much to be wary of in terms of where our food comes from and how it’s processed, transparency is important. Knowing something about the businesses you buy from is key to good health in terms of food safety, but also in terms of their authenticity of providing a halal product. Not all halal products are equal in that regard, and that’s what I liked about spending the morning at their plant. There was nothing to hide and everything to show- every door was opened and pipe explained (really) and all with an intense desire to show- not out of obligation. I think that’s critical to share.

And they thought it was critical to share a meal at the end of the tour. Talk about hospitality!

I knew the one thing I started to smell towards the end of the tour was something amazing being cooked- I thought perhaps they were testing recipes or something of that nature. As it turns out, Mr. Adam’s brother, “Abu J”, was preparing lunch for us- actually, it was more like a feast.

Rice with chicken, of course (above) and zucchini stuffed with ground…chicken (below).

This is no typical lunch, at least not a power lunch you’d find in most companies.

It felt like an international buffet was brought out to us: healthy salad, breaded tilapia, cajun French fries (yum) and of course, more chicken. Flavored deliciously. Soon thereafter we all had a conversation about spice.

Can I work here?

From right to left (Abu J, Mr. Adam and myself- with my eyes half open for some odd reason).

And there you have it- a hard-working family that has persevered to create a company with the idea of providing clean, all-natural poultry products not just to the Muslim community but to all people interested in consuming food that’s consumed well and has been processed well. That’s taking care of a product from farm to fork, quite literally- as you can see here…

What else would you like to know about how Crescent products are brought to your table?

Great job reporting-you get to go on the best field trips! *jealous* I appreciate the effort as my family eats Crescent chicken. One less thing to worry about….now if only you could get a glimpse into the live poultry farm!

@Shaheena- thanks! Inshallah the farm tour will be next 🙂

I always bought cresent chicken in chicago but in atlanta i m worried abt eating meat there is no cresent chicken seller in georgia plzz help me …where can i get zabiha halal meat

Al Barakah Halal Meat (Only Hand-Slaughtered)

Address: 739 Dekalb Industrial Way Suite 2155, Decatur, GA 30033

Phone: (678) 973-2299

This is very interesting and well presented; it’s good see a properly managed meat processing facility – but there is one very serious problem. How exactly are the live chickens slaughtered? This is very important, because there is only one way a chicken (or sheep, goat or cow) can be rendered halal for human consumption: the animal must be fully conscious, and it must be killed by having it’s throat slit with a hand-held knife wielded by a practicing Muslim. Under no circumstances may the animal be stunned, either by striking it with a hammer or using an electric stun-gun, before its throat is slit. Any form of stunning done before the animal’s throat is slit renders the meat from the animal haram for consumption by Muslims.

Thank you.

@Elizabeth- I agree and that’s why I do plan on going to the farm where the livestock is raised and hand-slaughtered, in order to see and share my observation. Insha’allah it’ll happen soon.

At the resent Sameer’s eats halal tour in Chicago I spoke to a representative from Crescent foods. I was curious to find out whether their chickens were stunned prior to slaughter. The lady I spoke to informed me that the chickens go through what she referred to as a water bath that has a mild electrical current running through it. Although this does not kill them it does slightly sedate them. She assured me that they do this in order to treat animals humanely and to prevent chickens from excess movement which could result in broken bones and subsequently bruised meat. After the water bath the chickens are slaughtered according to traditional Islamic practice deeming them Zabiha Halal. Their intentions and practices appear legitimate but Allah knows best.

As salamu alaikum

JazakAllahu khair for sharing this experience. Do you know if the crescent foods in Canada is affiliated with this one in America?

Salaam Saman,

Thank you for your question. We are completely unrelated and not affiliated with the Crescent company in Canada. Therefore, we are two separate companies. Crescent Foods has been in the US market for 18 years now, serving Premium Halal All Natural Chicken. At Crescent Foods, we pride ourselves in being the first company in the US to offer such a wide variety of Halal chicken products in premium packaging at retail and food service outlets across the country. We pride ourselves in raising and processing the chickens in humane conditions and ensuring that the entire farm-to-fork philosophy adheres to the strictest ethical guidelines.

Visit http://www.crescenthalal.com for complete information.

The creators of Crescent chicken thanks a lot for this fabulous and halal product , can it be supplied to the Walmart in Richardson Texas ? there is a huge need in this area , I have to drive further to another Walmart to purchase it, please continue to keep your chicken skinny and small that is what I look for because I know no hormones were fed to them!!

Asak wanted to see the most important aspect of your blog the actual hand slaughtering of the LIVE chicken by Muslims saying the Islamic prayer. Jak